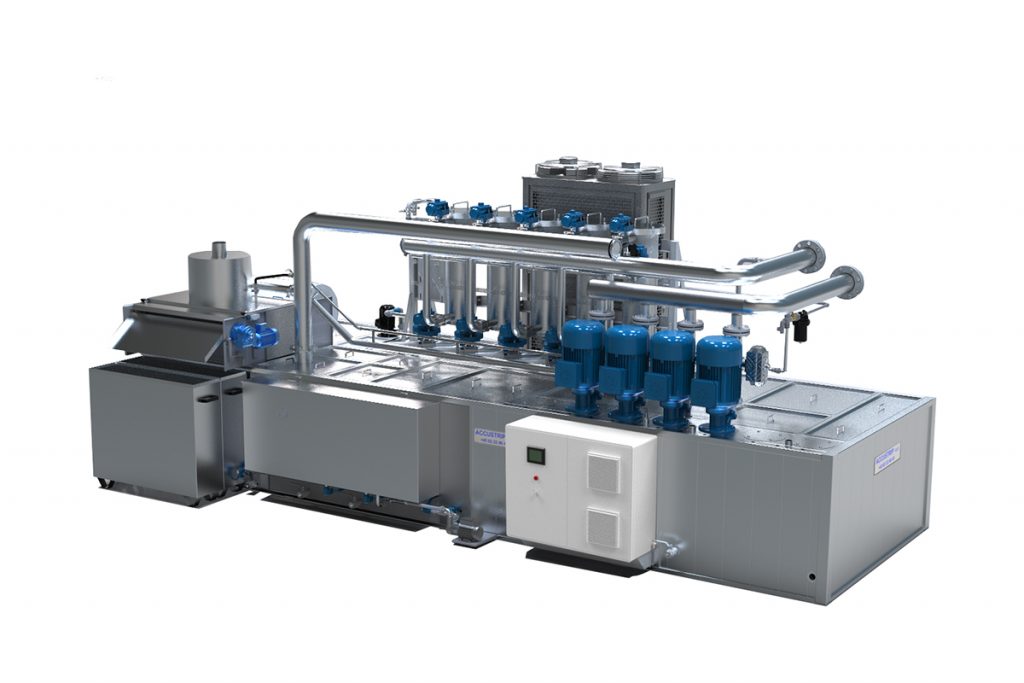

Full flow central plant

Filter your CNC machine park’s coolant in one central system.

Accustrip’s Full Flow Central Plant is connected to a number of CNC machines. This unique system ensures that all the liquid used by the machines is filtered instantly. The polluted liquid will be carried over a magnet separator. It will go through our unique patented oil separation system.

%

SEPARATION

Separate up to 95 % of all particles

%

SEPARATION

Separate at least 99 % of all leaked oil

FILTRATION

Filter the coolant with a fineness of 20 to 30 µm

- Longer tool edge lives and less machine wear

- Reduced risk of bacteria & reduced cleaning time

- Increasing liquid (coolant and emulsion) life time

- Filtering through self-cleaning stainless steel filter candles

- Filtering the liquid continuously with unlimited volume