Chip Shredder

Reduce the size of your chips

Maximize efficiency and sustainability with the Accustrip Chip Shredder, designed to reduce bulky metal chips into uniform sizes. This advanced system optimizes material handling, storage, and recycling, ensuring a cleaner and safer workplace while minimizing costs.

Why Choose the Accustrip Shredder?

✔ Reduce Chip Volume by Up to 8x – Save storage space and lower handling costs.

✔ Lower Transportation Expenses – Compact shredded chips decrease disposal costs.

✔ Enhance Workplace Safety – Eliminate sharp, bulky metal chips for a cleaner environment.

✔ Automate Operations – Minimize manual handling and optimize workflow.

✔ Support Sustainability – Contribute to a circular economy with recyclable metal chips.

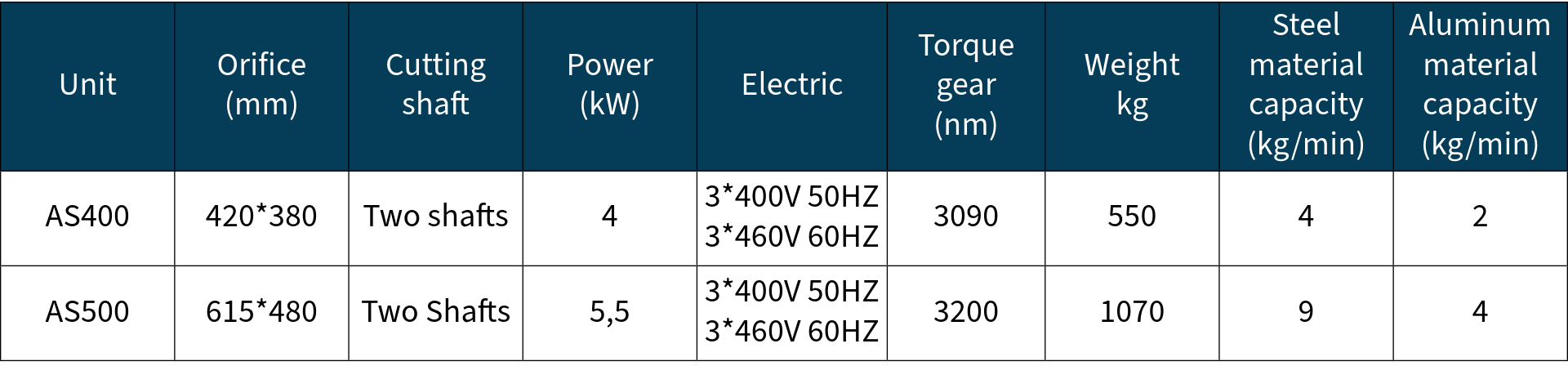

Technical Information

Advanced Shredding Technology

The Accustrip Shredder features high-torque blades or rotary cutters that efficiently break down metal chips into consistent sizes. The shredded material is seamlessly transported via an auger or conveyor, integrating smoothly into your production line.

Selecting the Right System

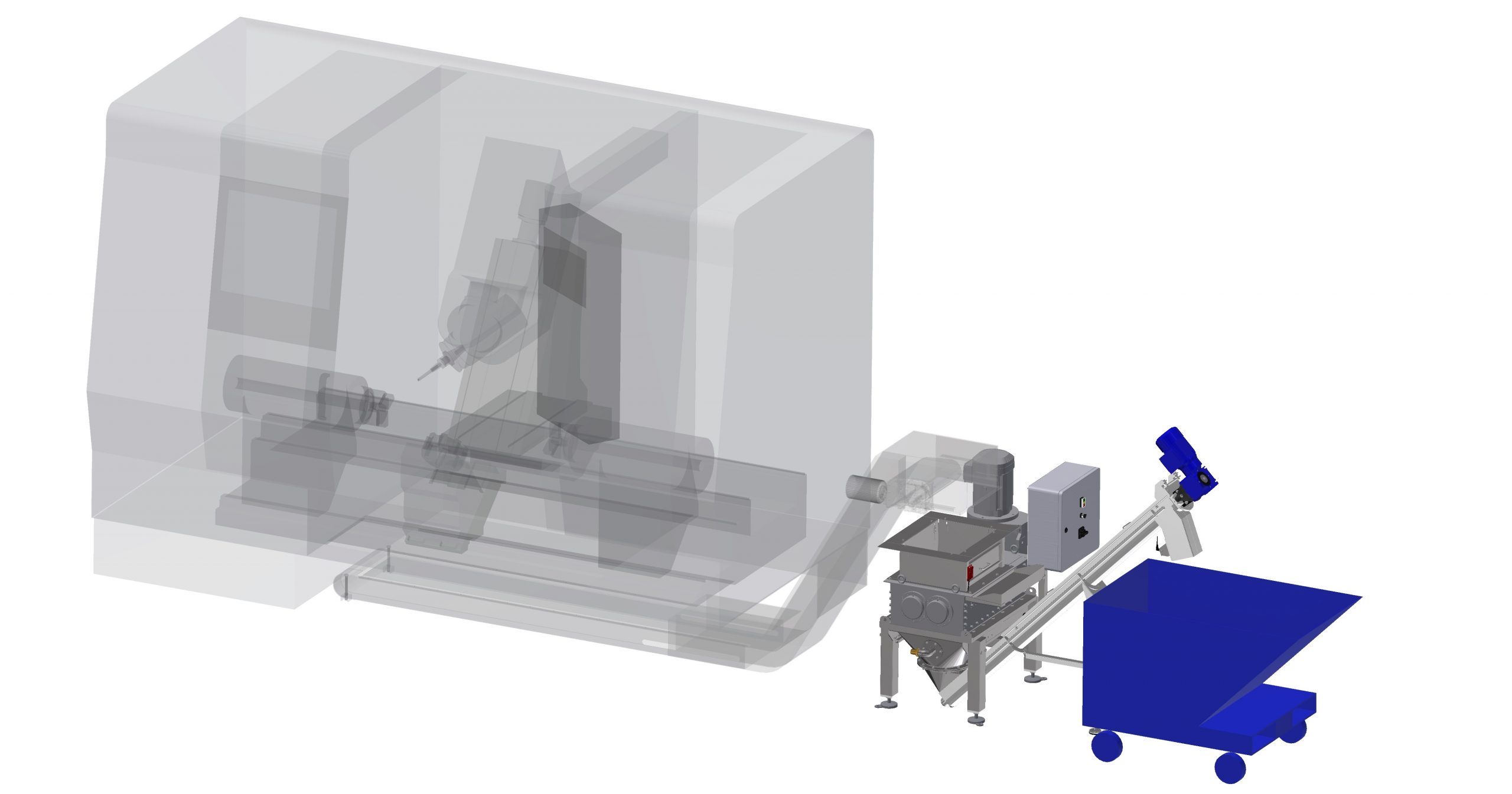

- Indirect Container (Auger System) – Indirect container is used when theres is less than 500 mm between container and conveyor outlet. This system transports shredded chips via an auger into a collection container, which can rotate 90° for space optimization.

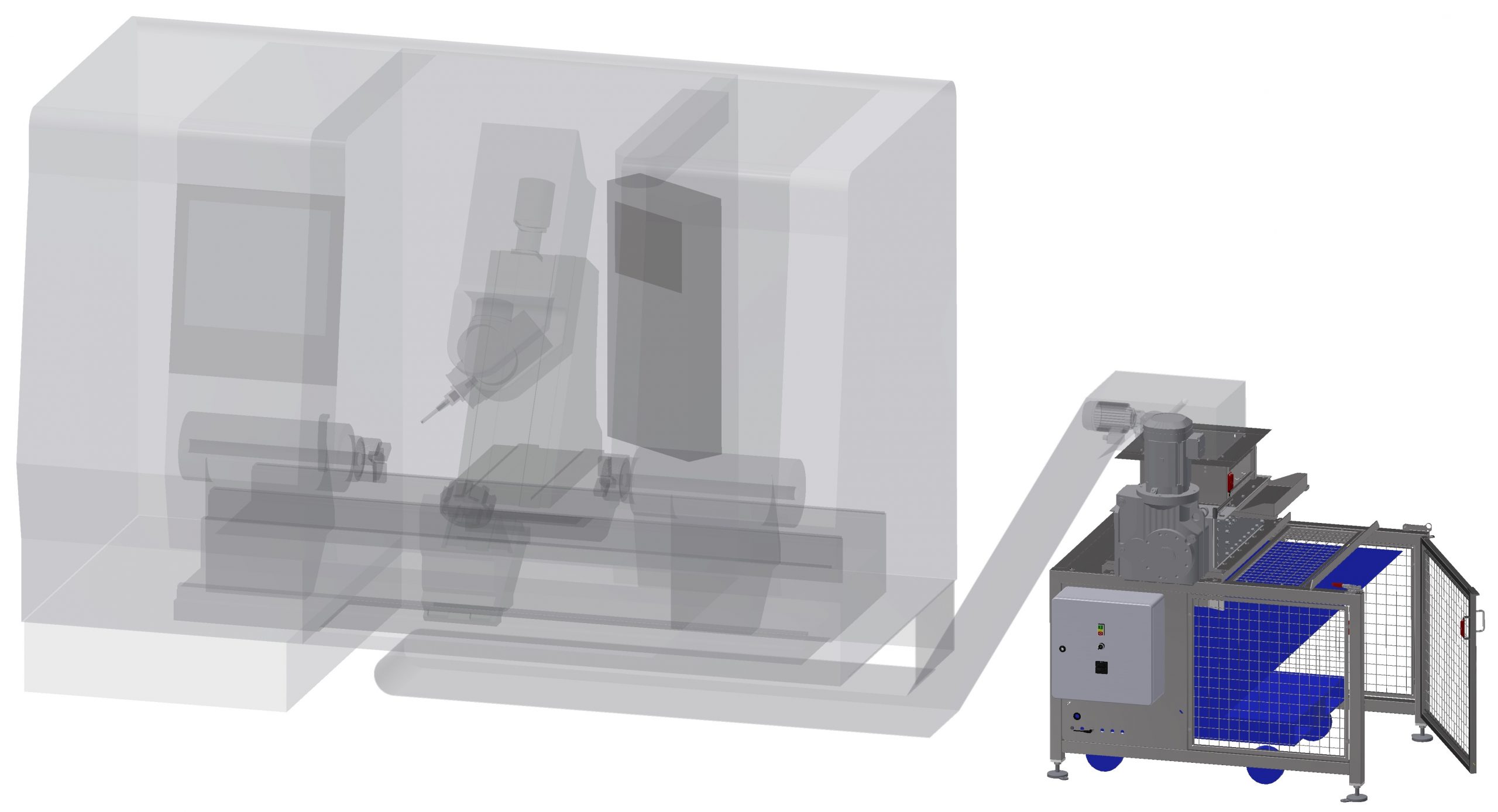

- Direct Container (Grid System) – For direct container discharge there must be at least 500 mm between container and conveyor outlet. Allowing shredded material to drop directly into a container without additional transport mechanisms.

Indirect Container

Direct Container