Coolant filtration

Introduction

At Accustrip, we have categorized all our products into two main areas: Coolant Filtration and Chips Management. You are currently on our Coolant Filtration page, where we are proud to offer a wide array of products specifically designed for efficient coolant management in CNC machinery. Our product range includes fully automatic cleaning systems, as well as various filter options such as self-cleaning and manual filters, high-pressure units, and magnetic and oil separators.

Additionally, we offer chillers, filter cloths, and absorbing products to support your filtration needs. One of our standout solutions is the full flow system, designed to enhance productivity while providing environmental benefits by effectively separating coolant emulsions from impurities. This comprehensive approach ensures optimal performance and sustainability in your operations. Also check out our Chips Management page.

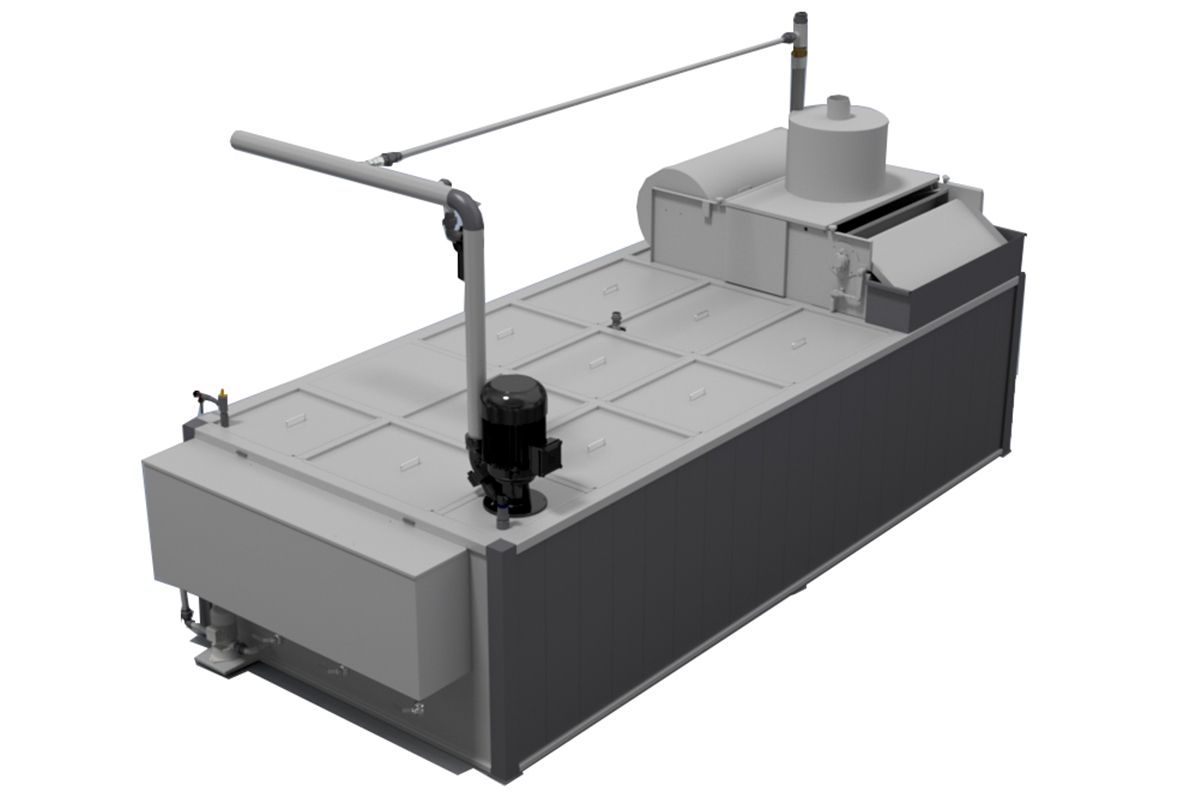

Full flow central plant

Fully automatic cleaning and various materials sorting for an unlimited amount of CNC-working centers.

Part flow central plant

Continuously filter parts of the cooling liquid with our Part Flow Central Plant.

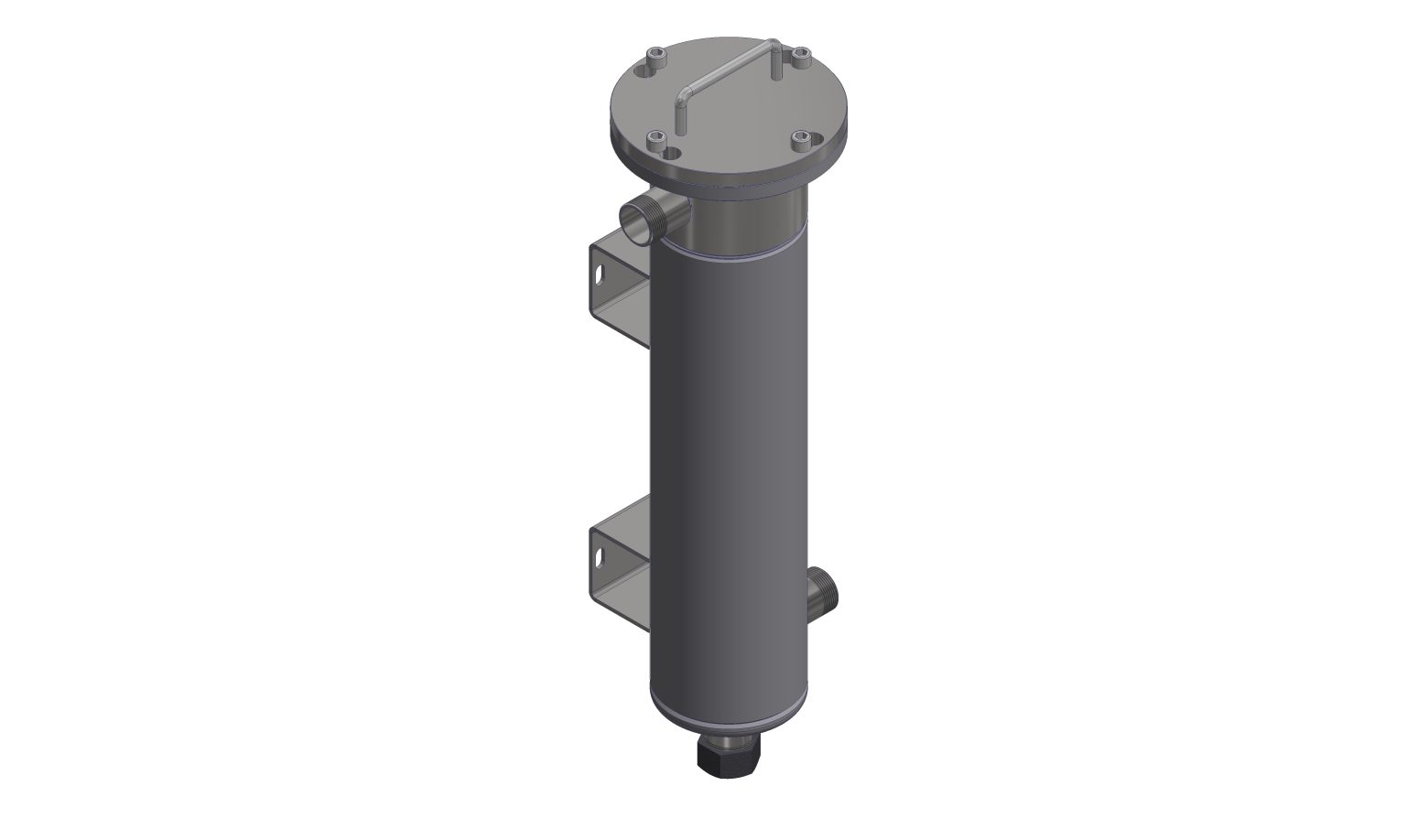

High pressure unit

Increase the pumping capacity of your CNC machine with our High Pressure Unit.

Filter 139 / 256 Self-clean

Remove impurities from your CNC machine’s coolant with our self-cleaning particle filter.

Filter 139 Manuel

Remove impurities from your CNC machine’s coolant with our highly effective Filter 139.

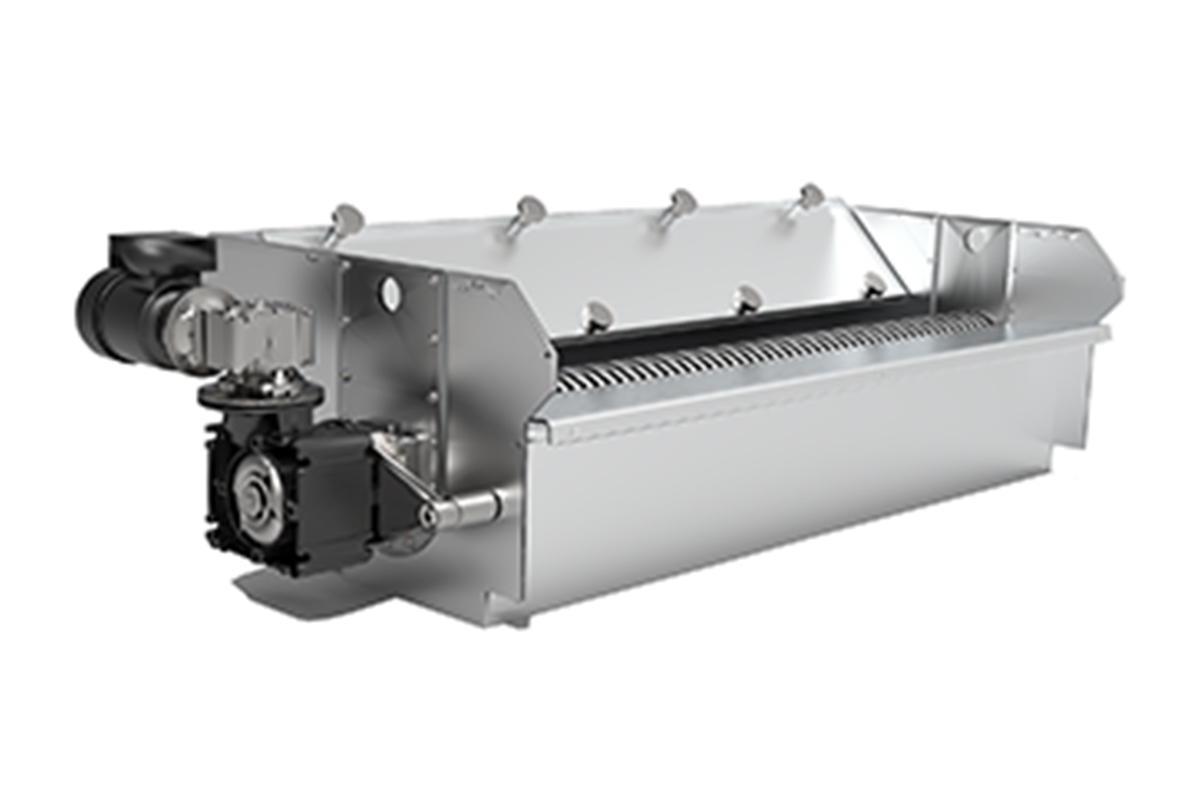

Band filter

Efficient particle filtration for your CNC machines with our fully automatic Band Filter.

Band filter unit (BFU)

Band Filter Unit with outlets in 3 different directions and a supply pump.

Magnetic separator

Efficiently separate your coolant from metal particles with our powerful Magnetic Separator

Oil separator

Experience Accustrip’s patented oil separation technology with an efficiency of 99 %

Filter cloth

Our wide selection of filter cloths ranges from heavy-duty nonwoven to lightweight single layer nonwoven.

Absorbing products

Separate several types of liquid with our wide selection of absorbing products.

We offer a variety of products designed for efficient coolant management in industrial settings. Our Full Flow Central Plant and Part Flow Central Plant provide central solutions for separating coolant emulsions from impurities, ensuring clean coolant flow and enhanced productivity. The Machine Connection integrates CNC machines with filtration systems, optimizing performance for seamless operations.

Our High Pressure Units deliver powerful coolant flow, essential for efficient machining processes. The Filter 139 systems, available in both Self-Clean and Manual versions, offer robust filtration solutions for different needs. Additionally, our Band Filters and Band Filter Units ensure continuous and efficient removal of particulates from the coolant.

Magnetic Separators and Chillers maintain coolant purity and temperature, while our Filter Cloth aids in the effective separation of particles from coolants. Designed specifically for CNC machines, our Coolant Filtration products work efficiently to filter and purify the coolants used in machining. This helps maintain the longevity and performance of the machinery, leading to more efficient operations and improved end-product quality.