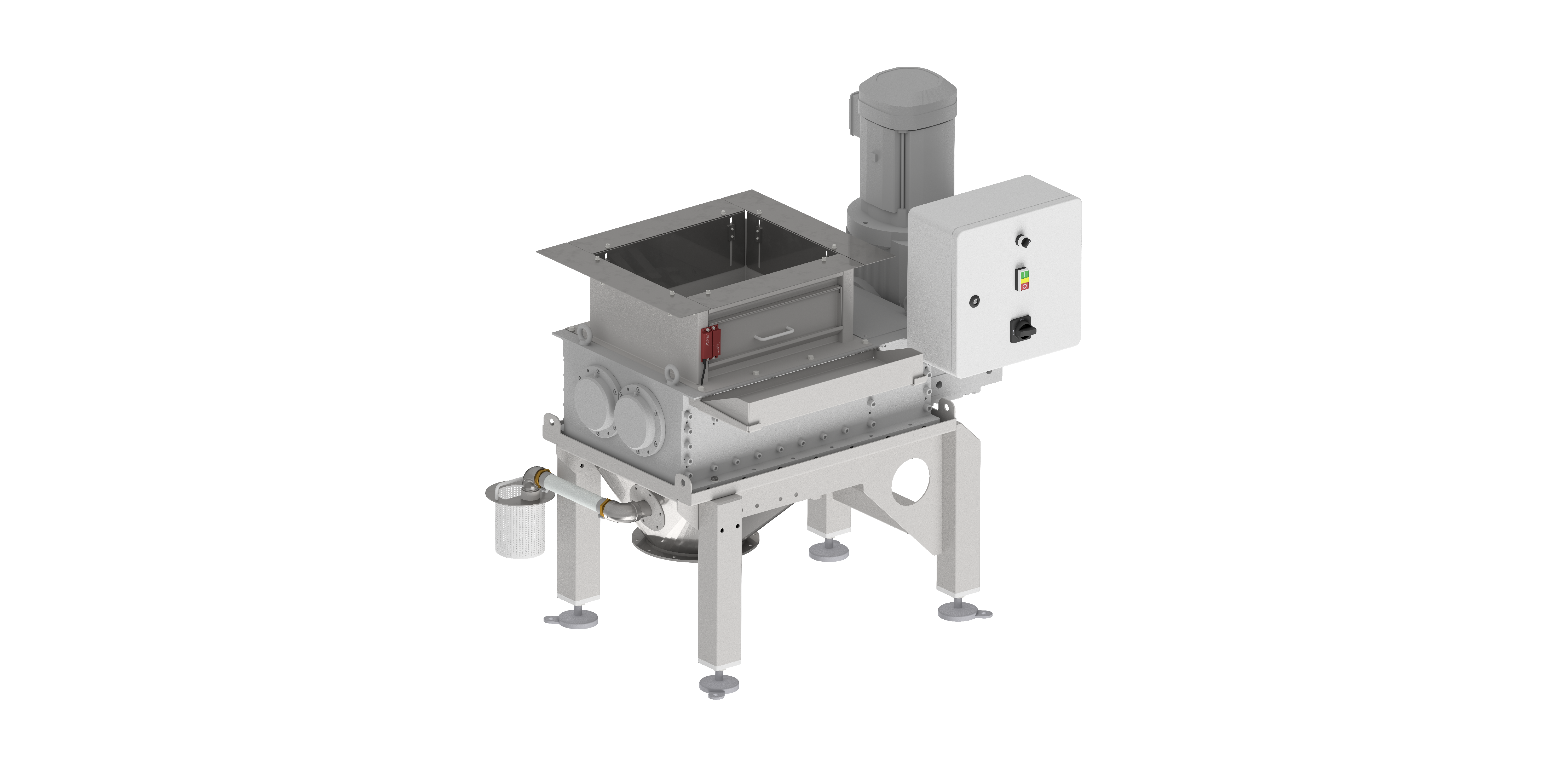

Shredder system

Optimize your chip handling

The Accustrip Shredder System is the perfect solution for companies who are looking to make their chip waste handling more efficient, by efficiently reducing chips to smaller and more manageable sizes – greatly extending the time between removals and making storage much easier. This system is also ideal for companies looking to streamline their chip disposal without major augmentations to production facilities, as the Accustrip shredder systems can be tailored directly to your exact needs.

The Accustrip Shredder System is the perfect solution for companies who are looking to make their chip waste handling more efficient, by efficiently reducing chips to smaller and more manageable sizes – greatly extending the time between removals and making storage much easier. This system is also ideal for companies looking to streamline their chip disposal without major augmentations to production facilities, as the Accustrip shredder systems can be tailored directly to your exact needs.

Benefits to your business

Maximized space and storage

By shredding metal chips into smaller pieces, you reduce their volume, allowing efficient storage and less emptying of chip containers. This saves valuable floor space and reduces clutter.

Enhanced production efficiency

The shredder minimizes metal chips, which prevent clogging in machines and conveyors, causing fewer interruptions in your production line, increasing productivity and reducing downtime.

Cost savings on disposal

Smaller, compact chips are easier and cheaper to dispose of, reducing the frequency and cost of waste management services. You can transport more chips per load, lowering shipping costs.

Improved workplace safety and cleanliness

Managing smaller chips reduces the risk of sharp metal fragments accumulating in the work area. The system helps maintain a clean and organized environment, enhancing safety and efficiency.

Benefits to your business

Maximized space and storage

By shredding metal chips into smaller pieces, you reduce their volume, allowing efficient storage and less emptying of chip containers. This saves valuable floor space and reduces clutter.

Enhanced production efficiency:

The shredder minimizes metal chips, which prevent clogging in machines and conveyors, causing fewer interruptions in your production line, increasing productivity and reducing downtime.

Improved workplace safety and cleanliness

Managing smaller chips reduces the risk of sharp metal fragments accumulating in the work area. The system also helps maintain a clean and organized environment, enhancing safety and efficiency.

Cost savings on disposal

Smaller, compact chips are easier and cheaper to dispose of, reducing the frequency and cost of waste management services. You can transport more chips per load, lowering shipping costs.

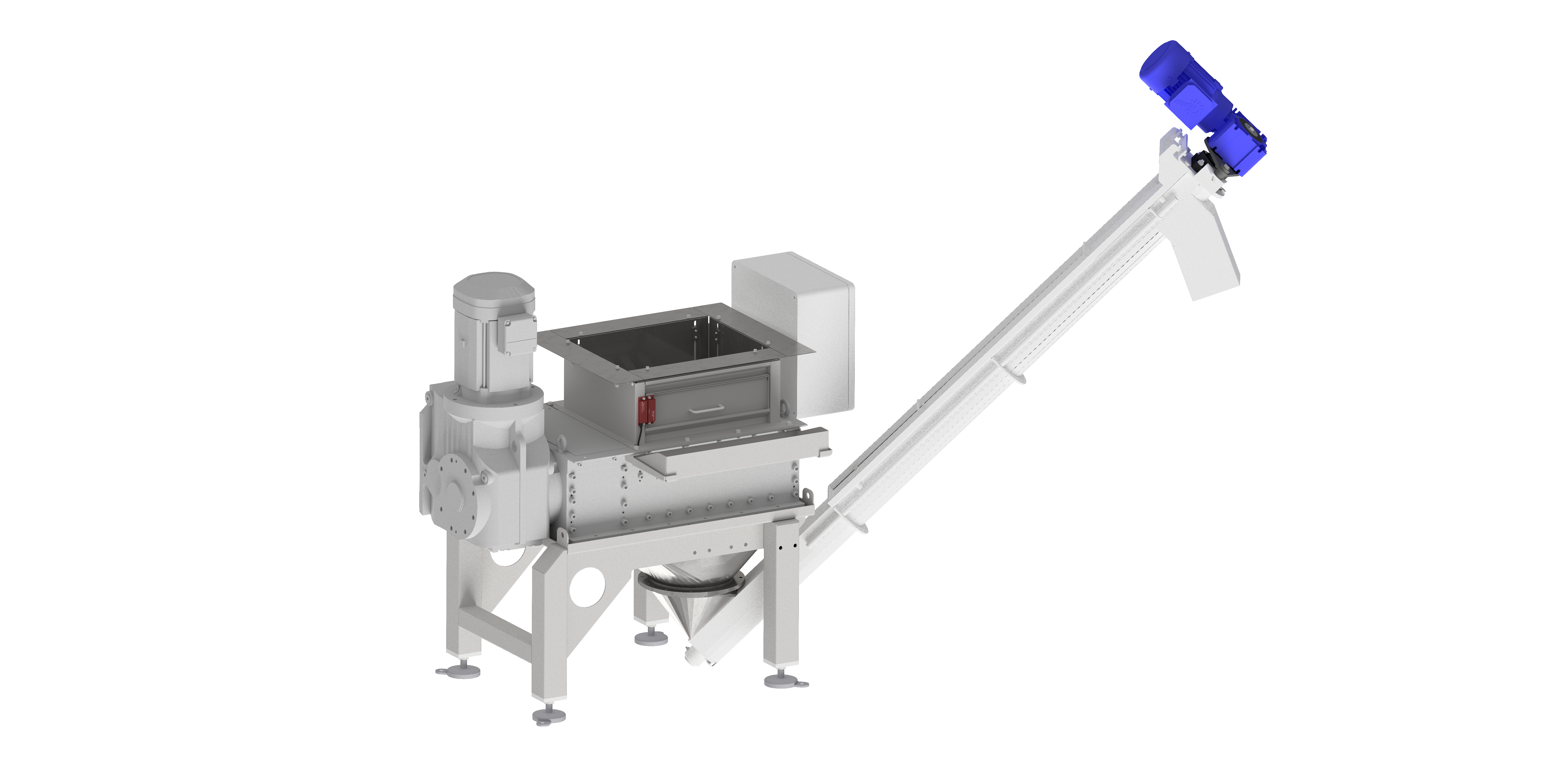

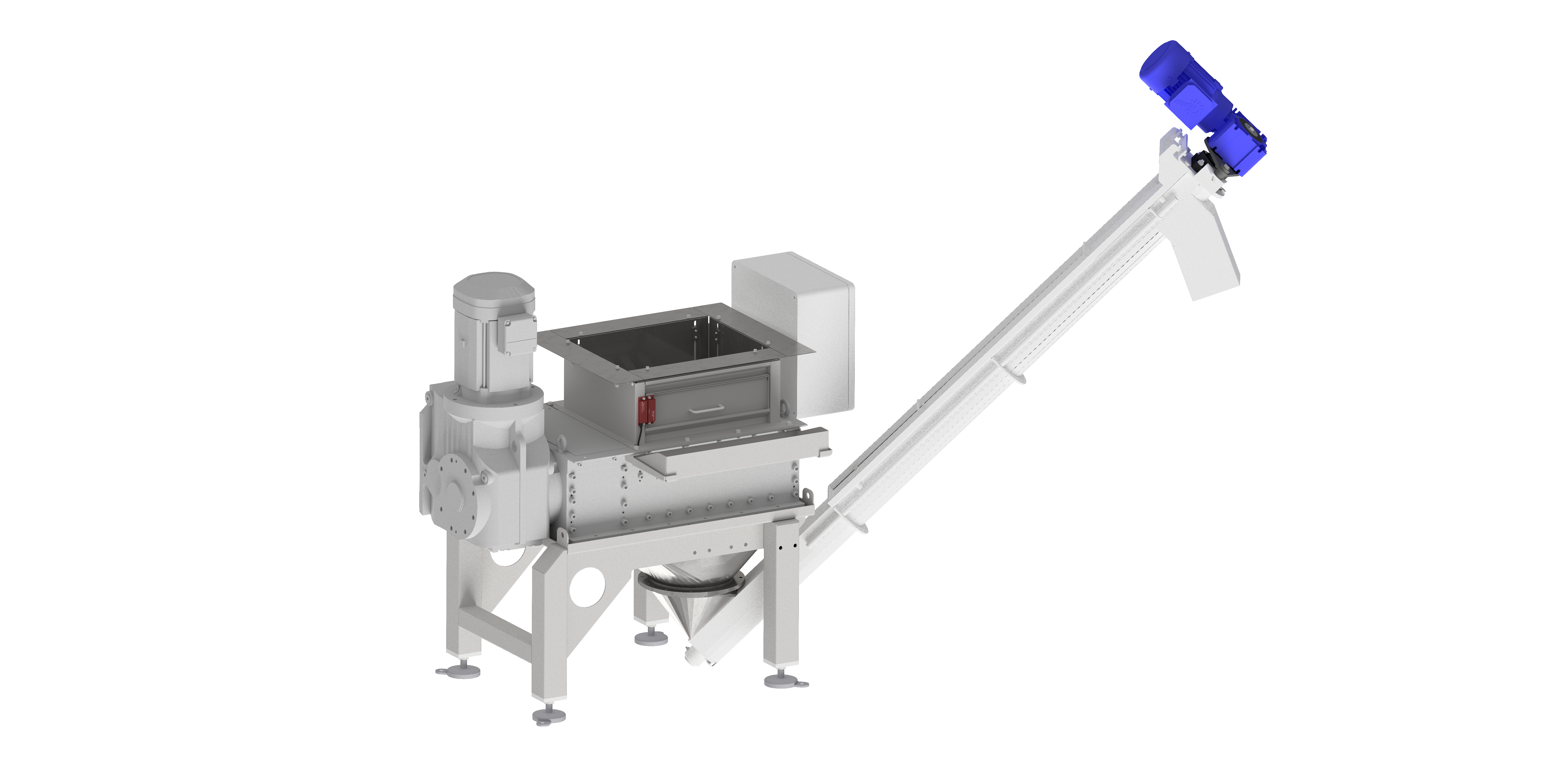

Shredder system with chip auger

For those with high chip production, we offer an optional chip auger. This auger can be added below the shredder to transport chips into a larger container, ideal for businesses with high-volume production. The discharge height of the chip auger is 84.6 inches, ensuring flexibility in storage solutions. This system helps reduce and manage metal waste, ensuring a clean and streamlined production environment

Benefits of the chip auger

Adaptability

With its adjustable height and rotating feature, the chip auger can fit directly into your production line, making installation quick and easy.

Storage Capacity

The optional chip auger enables you to transport metal chips to a larger container, reducing the frequency of disposal and improving productivity.

Less machine stress

The chip auger clears out shredded material, which reduces strain on the component, ensuring longer machine life and reduced maintenance cost.

Shredder system with chip auger

For those with high chip production, we offer an optional chip auger. This auger can be added below the shredder to transport chips into a larger container, ideal for businesses with high-volume production. The discharge height of the chip auger is 84.6 inches, ensuring flexibility in storage solutions. This system helps reduce and manage metal waste, ensuring a clean and streamlined production environment

Benefits of the chip auger

Adaptability

With its adjustable height and rotating feature, the chip auger can fit directly into your production line, making installation quick and easy.

Storage Capacity

The optional chip auger enables you to transport metal chips to a larger container, reducing the frequency of disposal and improving productivity.

Less machine stress

The chip auger clears out shredded material, which reduces strain on the component, ensuring longer machine life and reduced maintenance cost.

Key benefits

Powerful chip shredding

The shredder is designed to reduce metal chips into smaller, compact pieces, improving storgage and disposal efficiency.

Chip conveyor

The system includes a conveyor to transport the shredded chips. The conveyor discharge height can be adjusted according to your needs.

Stable frame construction

The sturdy frame holds the shredder securely in place, ensuring stable operation during the shredding process. This reliability is essential for heavy-duty application.

Chips container

A designated container stores the shredded metal chips, keeping your workspace clean and organized.

Sustainability benefits

The Accustrip shredder system not only enhances your production efficiency, but also contributes to a more sustainable operation. With our shredders, your work environment will contribute to a greener world.

Reduced waste volume

By shredding metal chips into smaller sizes, you minimize the volume of waste, allowing for efficient recycling and reducing landfill contributions.

Lower environmental impact

With fewer trips needed for chip disposal, you reduce transportation emissions, lowering your carbon footprint.

Efficient resource utilization

The compacted chips are easier to recycle, promoting better reuse of materials and supporting circular economy practices within your production process.

Investing in the Accustrip Shredder standalone system helps you streamline your operations, increasing efficiency and helping your business operating more sustainably while saving costs. This makes our solutions a smart choice for any business looking for an environmentally friendly solution to handle metal chips.

Interested?

We are ready to help!