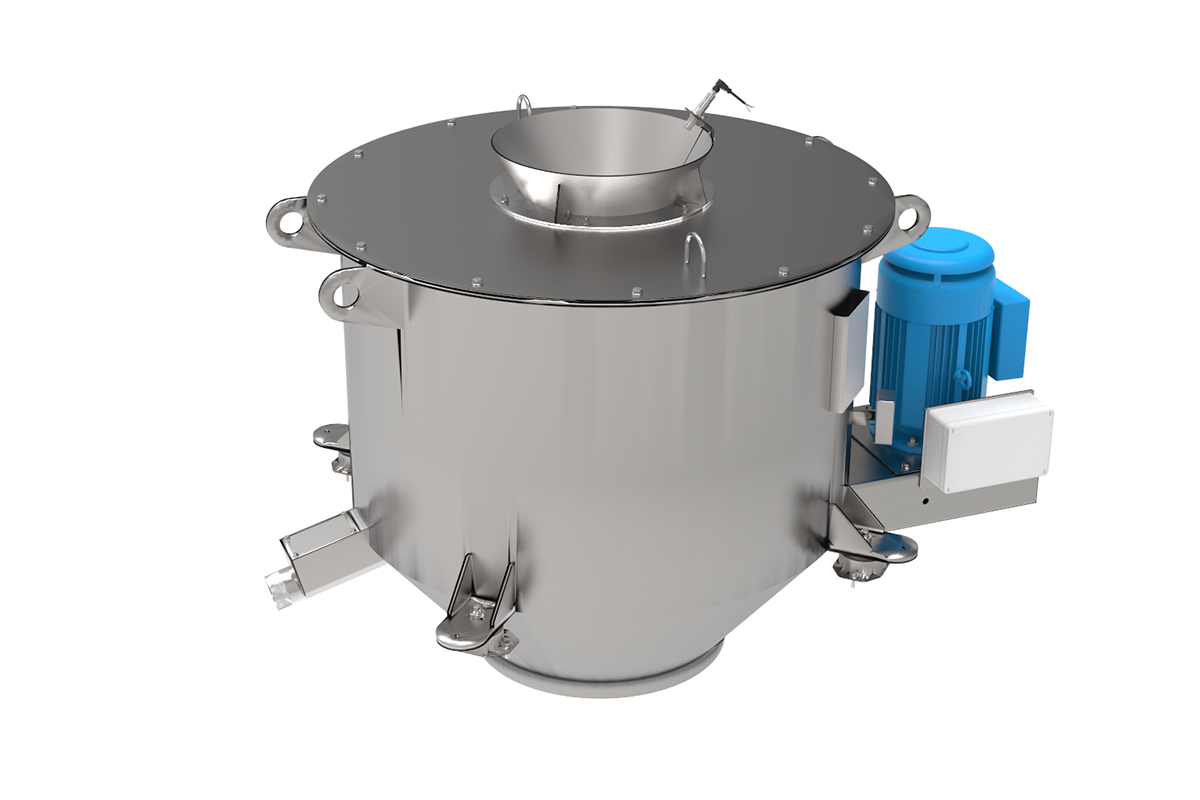

Chip Centrifuge

An effective way of separating metal chips from cooling liquid

Accustrip’s Chip Centrifuge separates metal chips that occur during metal cutting processes from coolant in a fully-automatic process. The wet chips / sludge fall over the infeed hopper into the drum of the lifting bottom centrifuge. At this point the chips meet the rotating lifting bottom and are pressed against the drum wall under high centrifugal forces.

The Chips Centrifuge

The hydraulically activated lifting bottom moves the chips and/or the sludge upwards to the slot sieve where the liquids are separated from the chips. After a few lifting cycles the dried chips are carried over the edge of the drum and leaves the centrifuge and goes into the container or discharge conveyor. An automatic and incredibly effective chip separator solution. The centrifuged liquid can be returned to the production or pumped back for further treatment.

- Continuous operation & long service life

- Fully automatic and in continuous operation

- Highly wear-resistant execution

- Best possible degree of dryness

- Compact design, self-cleaning & vibration-proof set-up

- Easy to maintain & low maintenance costs

Technical Information

The Parabolic Centrifuge

The Lifting Bottom Centrifuge

Benefits for Your Production

By returning centrifuged coolant to the production process or for further treatment, the Chip Centrifuge minimizes coolant loss and reduces disposal costs. Its robust and reliable operation improves overall efficiency while supporting sustainable practices.

Contact us today to learn more about how Accustrip’s Chip Centrifuge can enhance your chip and coolant management process!