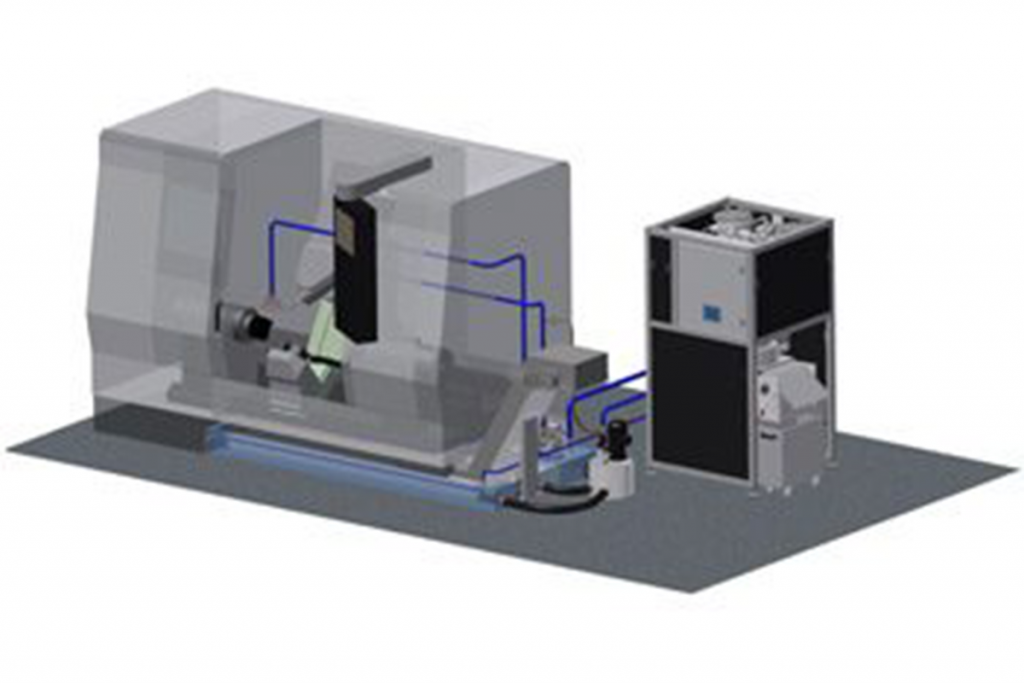

Microfil30

Filtration for up to 6 CNC machines with automatic, self-cleaning unit

Microfil 30, therefore, is based on the same principles as an Accustrip Full Flow Central Plant. Moreover, fluids are filtered through stainless steel filter rods with a filtration fineness of 20-30 microns.

%

SEPARATION

Separate at least 99 % of all leaked oil

CLEANING

Back flush cleaning every 15 minutes

BACK FLUSH

Back flush cleaning lasts only 20 seconds

FILTRATION

Filtration with a fineness up to 30 µm

Microfil 30

Self-cleaning filter rods operate by means of a timer-controlled backflushing. Specifically, a small amount of emulsion and compressed air is directed into the filter rods, which, in turn, performs a non-contact cleaning of the stainless steel filter rods. Additionally, a small amount of emulsion from the backflushing process is directed back to the chip conveyor in the CNC machine.

- Full automatic filtration system

- Effective back flushing of filter

- No pressure drop in the system

- Easy interface via harting plug

- Stainless steel unit incl, filter candle

Why Choose Microfil 30?

The backflushing system effectively directs waste emulsion back to the CNC machine’s chip conveyor, thereby simplifying waste management. Furthermore, this fully automatic filtration system eliminates pressure drops, integrates seamlessly via a Harting plug, and ensures a hassle-free user experience. Additionally, its compact, stainless steel design enhances both reliability and durability.

Boost Your CNC Machine Efficiency With Microfil 30

This system not only minimizes downtime but also reduces maintenance costs while ensuring optimal coolant cleanliness, thereby making it an essential component of a high-performing production line.

Moreover, upgrade your coolant filtration system today with Accustrip’s Microfil 30. For more information or to request a customized solution, contact us now!