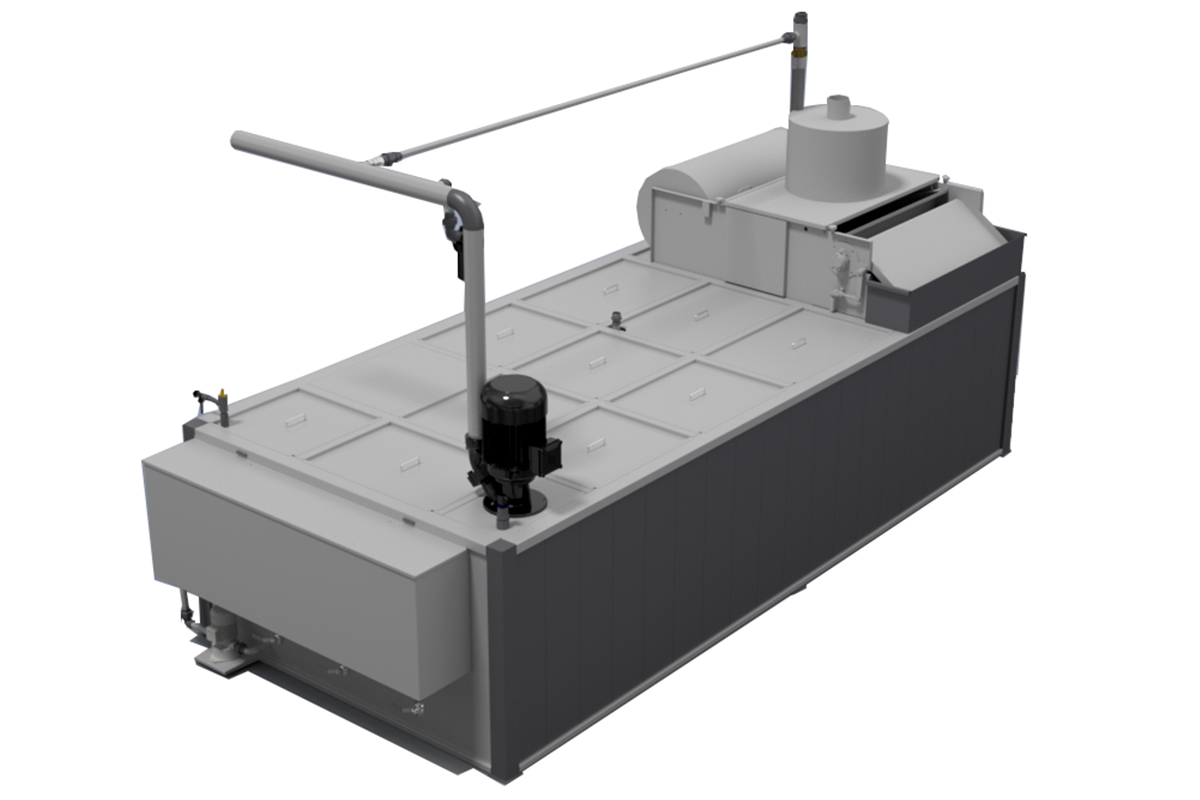

Band Filter Unit – TEST side – nyt design

Stationary band filtration unit

The new version of our proven Band Filter received the name BFU (Band Filtration Unit). The new BFU comprises a standard tank, a Band Filter with outlets in 3 different directions (270°, depending on the model), and a supply pump.

Improve your workflow with Accustrip`s Paper Band Centralizing system.

Separate small particles down to 70 µm from the coolant and lubricant and increase the lifespan of both coolant and lubricant as well as machine tools.

Like with the Full Flow Centralizing system and the Microfill Centralizing system, the Paper Band Centralizing system can be expanded with a Pre-separator in order to separate all chips from the coolant and lubricant.

BFU 500

Item no. xxx-xxxx

BFU 1000

Item no. xxx-xxxx

BFU 1000 XL

Item no. 140-0403

Function

The contaminated coolant and lubricant are pumped via the machine connection from the return pump station at each CNC machine to the Central Plant through a pipeline system consisting of a supply pipe and a return pipe. The pipeline system can be tailored to all types of productions, regardless of size and layout. The pipeline system is constructed of steel pipes and are automatically kept clean and tight without external maintenance.

In the first part of the Centralizing system, the small particles down to 70 µm are filtered out of the coolant and lubricant over a Paper Band filter that collects and disposes off the particles. This process proceeds continuously as the contaminated filter cloths are replaced automatically ensuring a constant flow.

After the particle filtration, the filtered liquid is passed on to the buffer tank, where it is

stored before being pumped back to the CNC- machine via the machine connection.

Since space is always the limiting factor in many production sites, the need for a compact plant with full flexibility arose. The BFU is constructed of stainless steel and can be expanded with up to 15 additional, optional modules (e.g. magnetic separator, chiller, oil separator, bigger tank, machine connection, holiday guard, and many more).

- Simpel and sturdy construction

- Designed as stand-alone version for one CNC-machine

- 100 % utilization of the filter cloth

- Lots of flexibility with many options

- Can hold filter cloth with roll Ø 510 mm.

- Fully automatic operation (alarm for missing filter cloth)

Advantages & benefits

- Fully automatic chip management

- No downtime

- Reduce cleaning procedures by 100%

- Separate & sort up to 8 different materials

- Gather all chip management in one place away from the main production area

- No chip conveyor in production area

Available options

- Machine connection (required)

The machine connection connects the CNC machine to the Central Plant. - Vacuum application for fine filtration 1000 (grinding application)

Sucks the liquid through the filter cloth for a finer particle filtering. - Magnetic Separator

The Magnetic separator separates magnetic particles such as cast iron or embers from the coolant and lubricant. - Oil Separator

The Oil Separator separates the tramp oil from the coolant and lubricant. - Oil belt skimmer

The Oil skimmer removes the oil from the surface of the liquid. - Automatic coolant concentrate mixer 1-10 %

Automatically mixes the optimal concentrate mixture. - Chiller

The Chiller maintains the correct coolant temperature and ensure higher tolerance levels, greater productivity, and minimizes rejected parts due to quality issues.

Technical specifications

| Type | CNC-machines | Max capacity (gal/min) | Filter fineness (um) | Tank volume (gal) | Width (in) | Length (in) | Heigth (in) |

| BFU 500 | 1 | 52 | 70 | 264 | 70 | 59 | 53 |

| BFU 1000 | 1 | 105 | 70 | 369 | 70 | 59 | 62 |

| BFU 1000 XL | 2 | 211 | 70 | 356 | 57 | 102 | 53 |

| BFU 1000 | 3 | 105 | 70 | 494 | 57 | 102 | 62 |

| BFU 1000 | 6 | 105 | 70 | 1056 | 57 | 191 | 62 |

| BFU 1000 XL | 10 | 211 | 70 | 792 | 57 | 129 | 72 |

| BFU 1000 XL | 25 | 211 | 70 | 1320 | 57 | 199 | 72 |

| BFU 1000 XL | 40 | 211 | 70 | 2113 | 57 | 305 | 72 |