Briquetting machine

Increase the value of your swarf with our Briquette extruder machine

Accustrip’s briquetting machine are developed to compress metal chips that occur during the metal cutting process. The mechanical briquette press can handle different types of materials and are available in versions with various pressure forces. The mechanical briquetting press machines are space-saving and easy to install.

The Briquetting Machine

The capacity of the briquetting press is material dependent. While the chips are pressed in the briquette process, the integrated pump is able to separate the coolant and pump it back to the processing machines or to a central plant. Various accessories and briquette equipment are available as options.

- Compact, small plant with lower cost on disposing

- Higher price for briquettes compared to chips

- Part of total chip handling plant or stand-alone model

- Briquettes almost free from coolant

- Briquettes size: between 60 x 40 mm and 80 x 80 mm.

- Briquettes length: between 30 and 90 mm

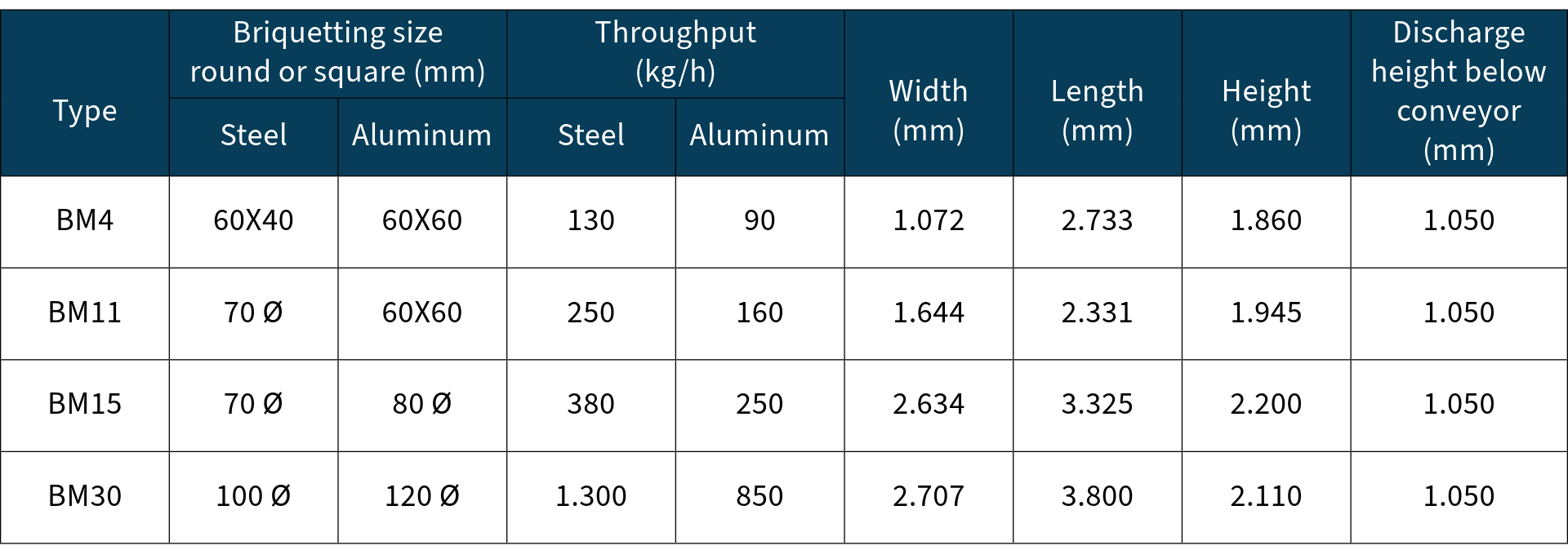

Technical Information

The Briquetting Machine Advantage

The briquetting process is highly efficient and offers several key benefits. During compression, the integrated pump separates coolant from the chips, enabling it to be reused in your processing machines or central plant. This reduces coolant waste and lowers disposal costs. The resulting briquettes are almost free from coolant, making them more valuable and easier to handle.

A Smarter Solution for Chip Management

Whether you need a standalone briquetting machine or a component for a comprehensive chip handling system, Accustrip offers the perfect solution. By transforming your swarf into nearly coolant-free briquettes, you not only reduce waste but also gain a more valuable byproduct.

Contact us today to learn more about how our briquetting machines can improve your operations and help you achieve higher profitability.