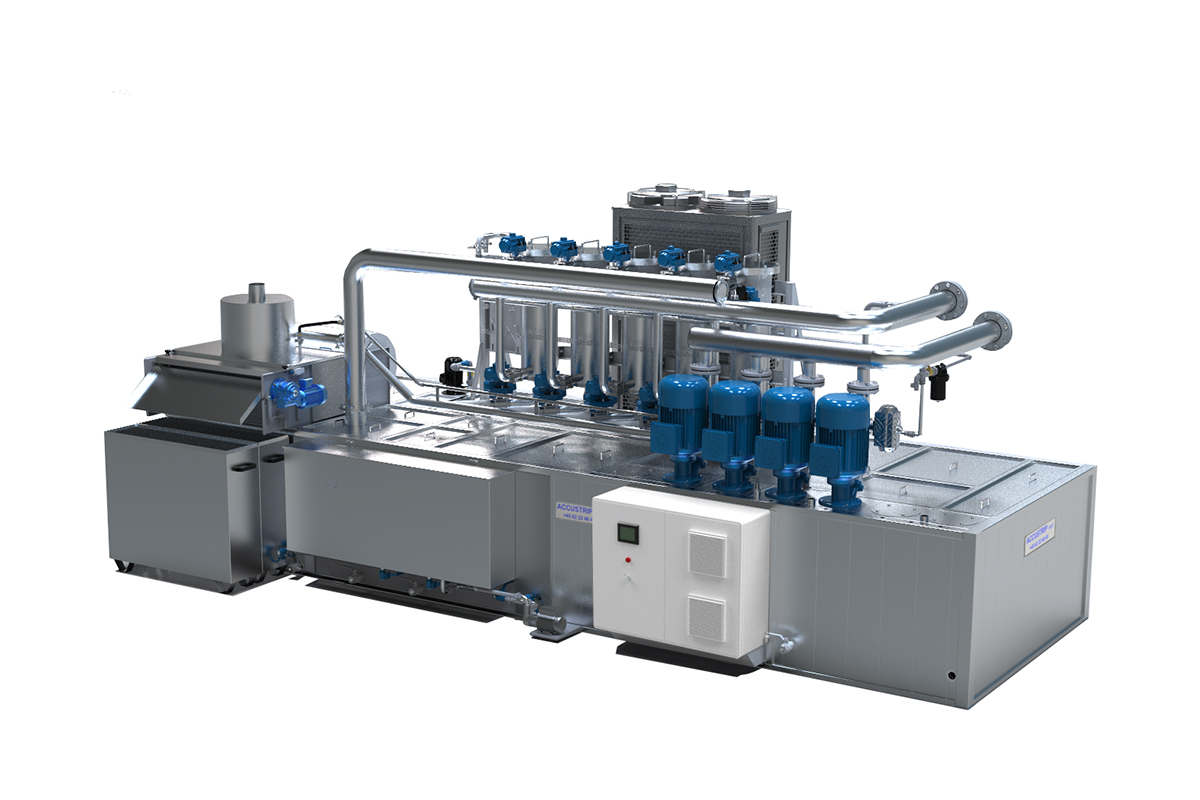

Full flow central plant

Filter your CNC machine park’s coolant in one central system.

Accustrip’s Full Flow Central Plant is connected to a number of CNC machines. This unique system ensures that all the liquid used by the machines is filtered instantly. The polluted liquid will be carried over a magnet separator. It will go through our unique patented oil separation system.

%

SEPARATION

Separate up to 95 % of all particles

%

SEPARATION

Separate at least 99 % of all leaked oil

FILTRATION

Filter the coolant with a fineness of 20 to 30 µm

- Longer tool edge lives and less machine wear

- Reduced risk of bacteria & reduced cleaning time

- Increasing liquid (coolant and emulsion) life time

- Filtering through self-cleaning stainless steel filter candles

- Filtering the liquid continuously with unlimited volume

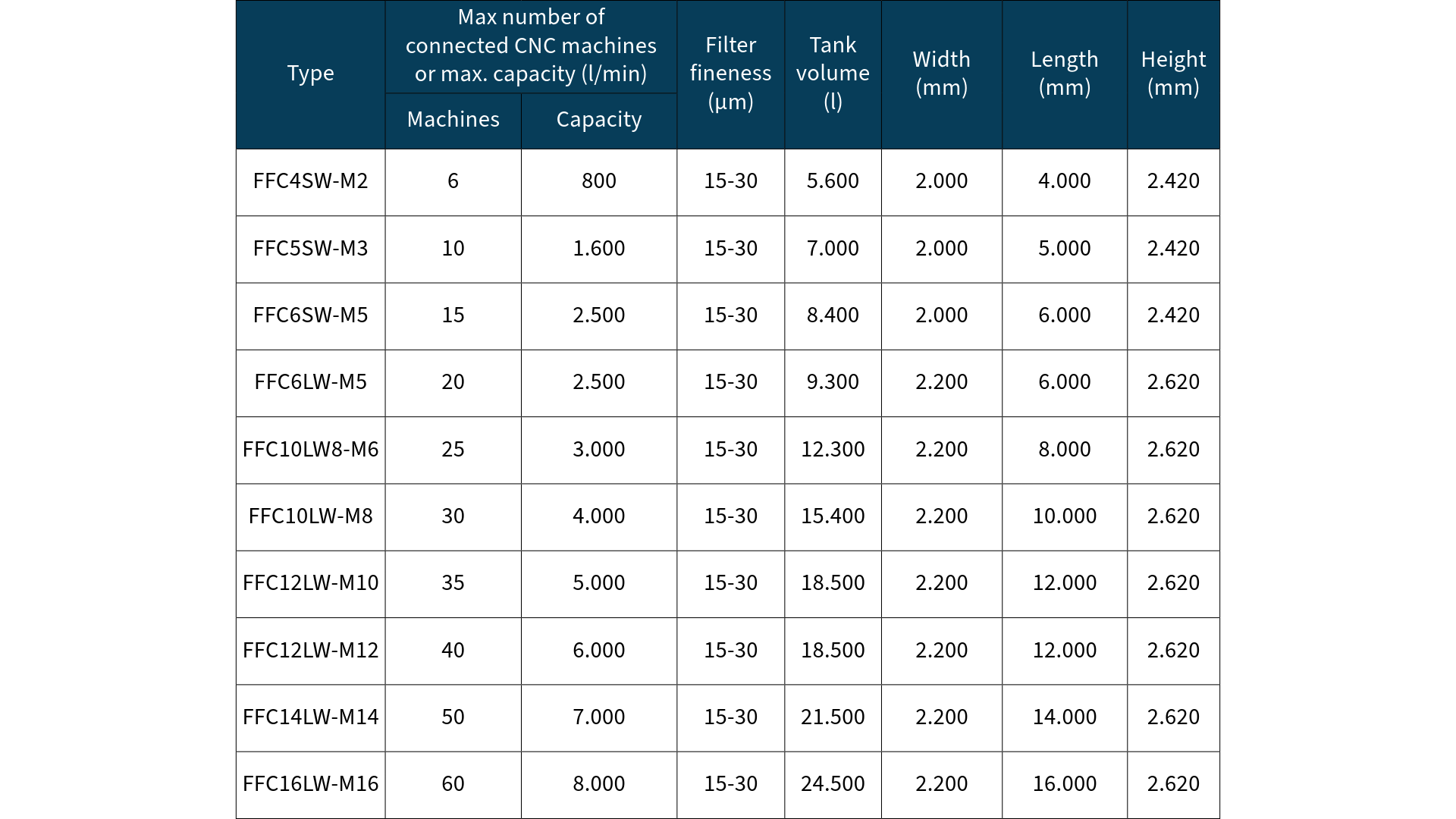

Technical Information

Improve Your CNC Machine Park’s Efficiency Today!

Invest in Accustrip’s Full Flow Central Plant to streamline your operations and maximize the lifespan of both your coolant and CNC machines. With our easy-to-maintain, highly efficient filtration systems, your business will experience improved production processes and a cleaner, more sustainable environment.

Contact us to learn more about how our solution can benefit your operations!