Chips Evacuation

Filter your CNC machine park’s coolant in one central system

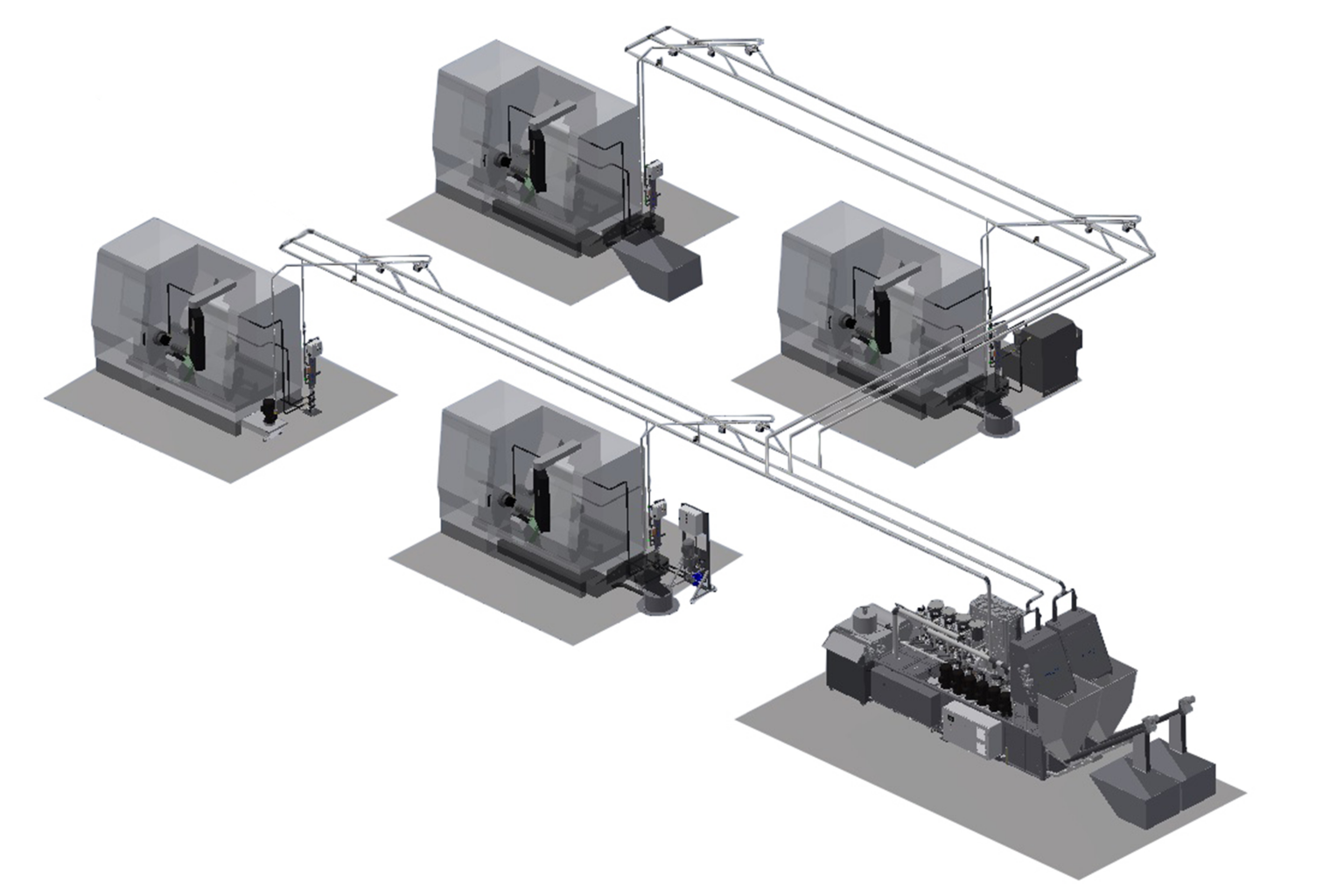

Accustrip’s Full Flow Central Plant is connected to a number of CNC machines. This unique system ensures that Nall the liquid used by the machines is filtered instantly.

%

SEPARATION

Separate a minimum 99 % of all leaked tramp oils

EMULSION

Fill the facility up with only 12.000 to 15.000 liters of emulsion

EMULSION

Change the emulsion every 2-3 years of production

PROTECTION

Filter the coolant with a fineness of 20 to 30 µm

Chips Evacuation

The polluted liquid will be carried over a magnet separator. It will go through our unique patented oil separation system, where after the coolant/emulsion will pass through stainless steel filter candles. The Full Flow Central Plant ensures effortless fluid handling – enhancing your CNC machine park.

This process happens continuously on a fully automatic basis – hence the name FULL FLOW.

- Less machine wear & longer tool edge lives

- Filtering the entire liquid continuously

- Increasing liquid (coolant and emulsion) life time

- No sludge cake: reduces the number of production stops

- Reduced risk of bacteria & no consumption materials

- Improved economy & environment

Cost-saving, environmentally friendly, and less maintenance

Imagine that you only need to purchase 12,000 to 15,000 liters of emulsion the first time the central facility is filled up, and then again when the emulsion is changed after 2-3 years of production. This smaller volume not only reduces costs for maintenance and service but also lowers the consumption of filter materials. At the same time, it minimizes all risks associated with bacterial and fungal growth in the emulsion, while reducing energy consumption for transport and cooling.

Additionally, another beneficial side effect of using an Accustrip Full Flow Central Plant is the reduced impact on the environment. Since an Accustrip Central Facility contains almost no moving parts, the intelligent control system constantly monitors the plant’s operation. As a result, service and maintenance become almost superfluous, allowing for a more efficient and flexible production process.

Filtration solutions that meet your require-ments

Whether your production involves processing cast iron, aluminum, steel, titanium, or other materials, Accustrip develops and delivers a central filtration system that is tailor-made to suit your specific needs. Our plants are modular by design, which allows them to be supplied with a variety of options, such as a magnetic separator, cooling unit, automatic liquid filling, and additional pumps (either as a backup or to increase the plant’s capacity). Furthermore, all central plants are constructed from stainless steel (AISI 304) and consist of standard components, making maintenance and plant expansion both easy and cost-effective.

In addition, the filter candles are self-cleaning through a timer-controlled back-flush. During this process, a small amount of emulsion and compressed air is directed into the filter candles, performing a non-contact cleaning of the stainless steel filter candles. The small amount of emulsion produced during back-flushing is then redirected back to the band filter, ensuring efficient operation and minimal waste.