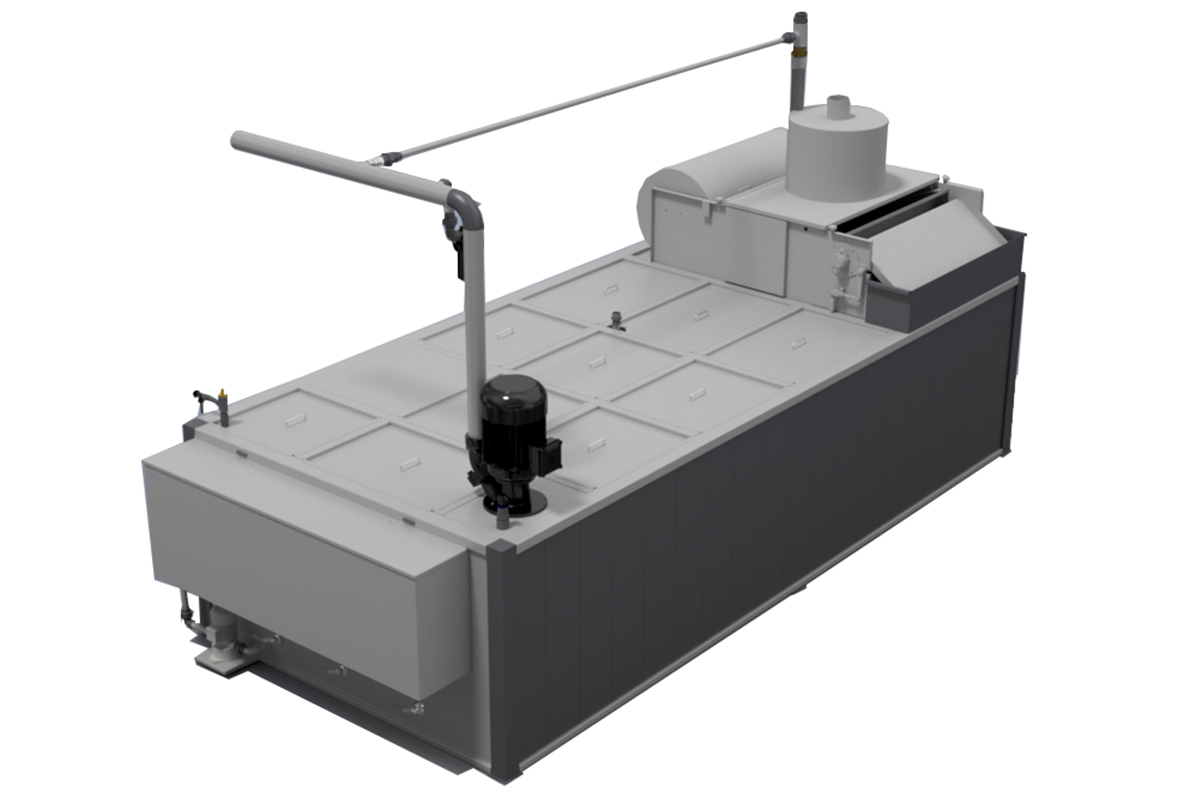

Part flow central plant

Continuous central filtration of parts of the liquid

Accustrip’s Part Flow Central Plant is an innovative solution that enables companies in the metal working industry to filter coolants, washing waters and other types of liquids from multiple CNC machines in one central system. It is particularly suitable for cleaning high volumes of liquids.

%

SEPARATION

Separates at least 99 % of all leaked oils before the liquid is led back to the reservoir and then pumped back to the CNC machines

%

SEPARATION

Filters typically 6-10 % of the total liquid volume in the sump each time it passes through the system afterwhich it is mixed with the unpurified amount

Part flow central plant

It is a solution that allows for clear improvements in productivity and reductions in production cost. As with the full-flow central systems, a pump station is placed at or next to the machine, which leads the polluted liquid to the central system via a pipe system.

- Prolonging the edge life of the tools

- Less wear and tear of the machines

- Filtering the surface liquid continuously

- Always the same liquid level on processing machines

- Prolonging the life of the process liquids